In an era where environmental concerns dominate public discourse, innovative packaging solutions have taken center stage. Among these, leno mesh bags have gained increasing popularity due to their practicality and eco-friendliness. Constructed from woven polypropylene (PP), leno mesh bags offer a versatile alternative to single-use plastics. Their unique structure not only makes them durable but also allows for ventilation, prolonging the freshness of perishable products. This Mahira Polyglobal LLP explores the features, benefits, manufacturing processes, and various applications of leno mesh bags while highlighting the crucial roles played by PP bag manufacturers and leno mesh bags manufacturers in promoting sustainability.

Understanding Leno Mesh Bags: The Fabric and Features

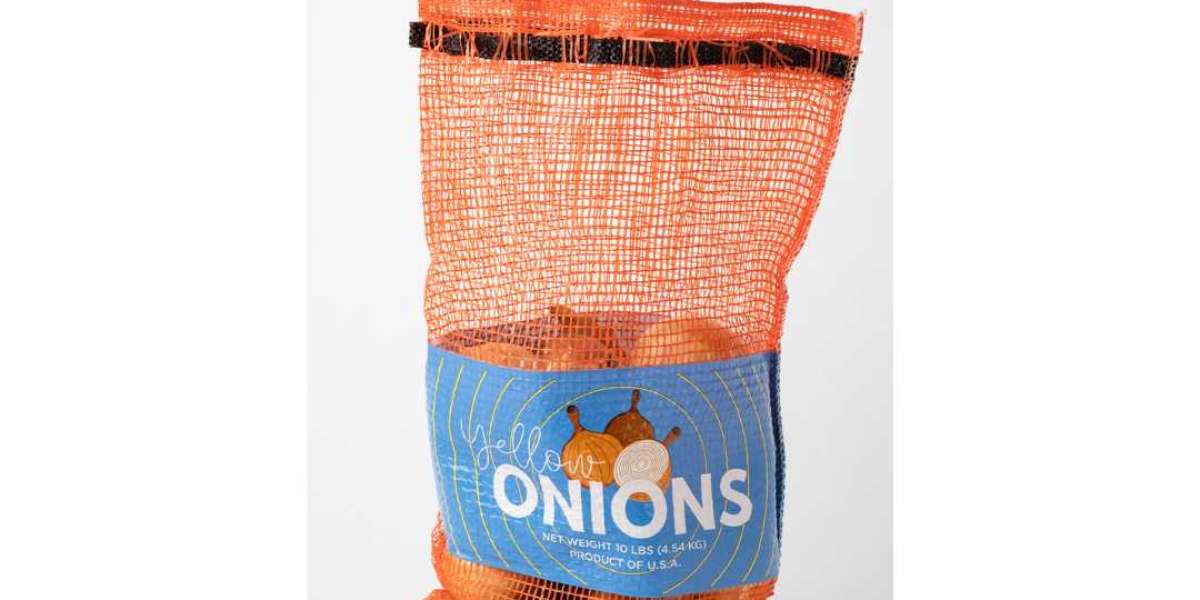

Leno mesh bags are distinctive for their woven construction, which creates a grid-like pattern through the interlacing of PP threads. The resulting mesh for bags offers visibility, allowing customers to see the contents inside, while also providing breathability. This is crucial for products like fruits and vegetables, as it helps minimize moisture buildup, which can lead to spoilage.

The durability of leno mesh bags is another prominent feature. Despite being lightweight, they can withstand heavy weights and rigorous handling, making them suitable for a variety of uses, from agricultural transportation to everyday shopping. Their versatility extends to sizes and shapes, enabling manufacturers to produce bags that cater specifically to different consumer needs. This adaptability, combined with their practical benefits, has led to leno mesh bags gaining a foothold in various sectors, especially as sustainability becomes a priority for both consumers and businesses.

The Role of PP Bag Manufacturers in the Production of Leno Mesh Bags

The PP bag manufacturers play an essential role in the production and distribution of leno mesh bags. The process begins with the extraction and preparation of polypropylene resin, which is the primary material for these bags. The resin is then melted and extruded into thin threads. These threads are woven together in such a way as to produce the characteristic mesh structure of leno bags.

Quality control is paramount in this manufacturing process. Each batch of bags is rigorously tested to ensure that it meets industry standards for strength and durability. Manufacturers often incorporate feedback from customers to refine their products continually. This focus on quality helps in establishing trust among consumers who choose leno mesh bags as a reliable and long-lasting alternative to traditional plastic bags.

Another important aspect is the shift towards sustainability that many PP bag manufacturers are adopting. Many are investing in eco-friendly practices, such as using recycled materials in the production of leno mesh bags and implementing energy-efficient manufacturing processes. By embracing these methods, manufacturers not only contribute to reducing environmental impact but also appeal to a growing consumer base that prioritizes sustainable purchasing decisions.

Diverse Applications of Leno Mesh Bags: From Farms to Retail

The versatility of leno mesh bags allows them to be utilized across various industries. In agriculture, these bags have become a staple for harvesting and transporting crops. Products like onions, potatoes, and even seafood benefit significantly from the breathable design, which helps maintain freshness and quality during transport and storage.

In the retail sector, supermarkets and health food stores increasingly offer leno mesh bags to customers. These bags are particularly effective for bulk items like grains, nuts, and produce, as they eliminate the need for single-use plastic alternatives. Retailers benefit from providing a sustainable option that aligns with consumer preferences, thereby enhancing their brand image and customer loyalty.

The potential applications don’t stop there. In households, leno mesh bags serve as excellent organizational tools. From storing toys and craft supplies to holding laundry items, these bags provide a practical, eco-friendly solution that helps reduce clutter. Leno mesh bags are also used by crafters for organizing materials, further showcasing their ability to cater to various consumer needs.

Environmental Benefits of Leno Mesh Bags: A Greener Choice

One of the most compelling arguments for the adoption of leno mesh bags is their significant environmental benefits. Unlike traditional plastic bags, which often contribute to landfill waste and pollution, leno mesh bags are reusable and designed for a long lifecycle. The ability to wash and reuse these bags numerous times drastically reduces the demand for single-use plastics.

Moreover, leno mesh bags are typically made from recyclable polypropylene. This means that when the bags reach the end of their useful life, they can be recycled, thereby feeding back into the production cycle. Many communities have initiated recycling programs that accept these bags, encouraging proper disposal and significantly minimizing the ecological footprint associated with plastic waste.

Additionally, the manufacturing processes adopted by PP bag manufacturers often emphasize waste reduction and energy efficiency. By minimizing the resources required to produce each bag and encouraging reuse, businesses that utilize leno mesh bags contribute meaningfully to a more sustainable future. This sets a powerful example for consumers, urging them to think critically about their packaging choices.

Customization and Branding Potential of Leno Mesh Bags

The ability to customize PP Leno Mesh Bag Manufacturers presents exciting opportunities for businesses looking to enhance brand visibility. Many manufacturers now offer options to print logos, designs, and messaging directly onto the bags. This transforms simple packaging into a marketing medium that can attract consumer attention while reinforcing brand identity.

For businesses, utilizing branded leno mesh bags can have several benefits. They act as walking advertisements, increasing visibility each time customers use them. This not only enhances brand reach but also fosters a sense of loyalty among consumers who appreciate the company's commitment to sustainability.

Additionally, the customization options extend beyond aesthetics. Businesses can collaborate with leno mesh bags manufacturers to create bags tailored for specific uses or for particular target audiences. This could range from smaller bags designed for gourmet snacks to larger ones aimed at the bulk grocery market, meeting specific consumer needs in a highly competitive marketplace.

Consumer Trends Favoring Leno Mesh Bags

As consumer awareness of environmental issues continues to grow, there is a noticeable shift toward purchasing sustainable products, with leno mesh bags at the forefront. Shoppers are increasingly aware of the impact of their choices on the planet and seek out alternatives that align with their values. This change is reflected in the increasing sales of leno mesh bags, as they provide a practical solution for those wishing to reduce their plastic consumption.

Social media influences this trend significantly. Many consumers share their eco-friendly practices online, fostering a community that values sustainable living. By incorporating leno mesh bags into their routines, consumers not only contribute to reducing plastic waste but are also part of a broader movement toward conscious consumerism. Retailers that promote these bags can engage in meaningful dialogues with their customers, showcasing their commitment to environmental responsibility.

Moreover, government regulations banning or limiting the use of single-use plastics in many areas urge businesses and consumers to seek sustainable alternatives. Leno mesh bags not only meet these needs but do so in a stylish and functional manner. This trend positions them as a staple in the sustainable market, ensuring they retain relevance as consumer preferences evolve.

Conclusion: The Future of Leno Mesh Bags in Sustainable Packaging

As the demand for sustainable solutions continues to rise, Leno mesh bag stand out as a practical, eco-friendly option for consumers and businesses alike. Their unique features, adaptability, and environmental benefits make them an essential component of modern packaging strategies. The proactive efforts of PP bag manufacturers and leno mesh bags manufacturers to create high-quality, eco-conscious products have further solidified their place in the market.

By adopting leno mesh bags into daily practices, consumers can take tangible steps toward reducing their impact on the environment. The ongoing evolution of these bags—spurred by innovations in manufacturing and consumer demand—suggests a bright future for leno mesh bags as they continue to play a vital role in the global shift toward sustainable packaging solutions.

Frequently Asked Questions (FAQs)

1. How do leno mesh bags contribute to sustainability?

Leno mesh bags are reusable and made from recyclable polypropylene, significantly reducing the reliance on single-use plastics. Their longevity and ability to facilitate recycling help minimize waste and environmental impact.

2. Can leno mesh bags be customized for specific branding needs?

Yes, many leno mesh bags manufacturers offer customization options that allow businesses to print logos and designs on the bags, enhancing brand visibility and creating marketing opportunities.

3. What types of products are best suited for leno mesh bags?

Leno mesh bags are excellent for a variety of items, particularly fresh produce, bulk goods like grains and nuts, and even household items. Their breathable design helps maintain the quality of perishable products.

4. How can consumers properly recycle leno mesh bags?

Consumers can recycle leno mesh bags by checking local recycling programs that accept polypropylene materials. It’s important to clean the bags before recycling to ensure they are free from contaminants.