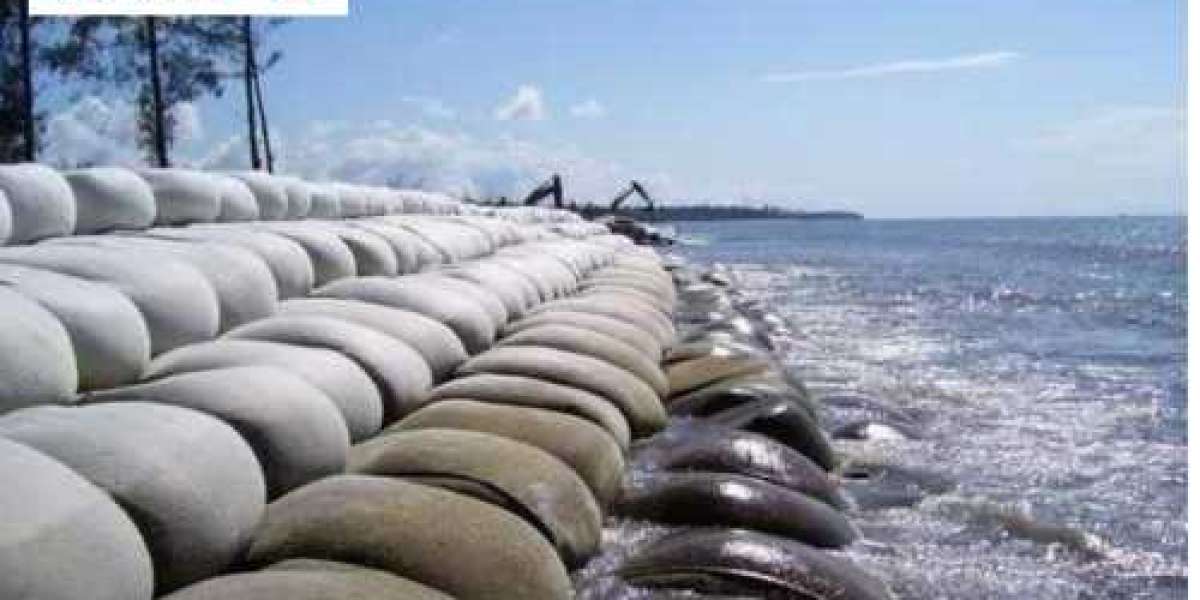

Geotextile bags, often referred to as geo bags or geotextile sand bags, are widely regarded for their versatility and efficiency in a variety of applications, including erosion control, sediment management, and even temporary flood barriers. Their durability and functionality significantly depend on the way they are maintained over time. For both home and commercial projects, understanding the best practices for maintaining these bags can enhance their longevity and effectiveness.

Understanding Geotextile Bags

Before delving into best practices, it’s essential to understand what geotextile bags are made of and their intended use. Typically, the bags are constructed from woven or non-woven geotextiles, materials designed to filter and drain while providing structural support. Manufacturers, or Geo bag manufacturer as they are commonly known, produce these bags in various sizes and specifications, tailored for different projects.

Best Practices for Maintenance

Regular Inspection

The primary step in keeping geotextile bags in optimum condition is regular inspection. Inspect bags for any signs of wear, tear, or damage. Look for rips, holes, and any signs that the structural integrity of the bag has been compromised. Early detection of damage allows for timely repairs or replacements, thus preventing more extensive issues.Proper Installation

Although maintenance is essential, proper installation lays the groundwork for durability. Ensure that geotextile sand bags are filled correctly and placed securely in their designated location. The positioning should allow for optimal drainage and sediment filtration while minimizing exposure to extreme weather conditions.Preventative Measures

Take proactive measures to protect the bags from potential damage. This includes using protective coverings or barriers if they are installed in high-traffic areas or exposed to harsh environmental conditions such as heavy rainfall or strong winds. Implementing vegetation around the bags can also help prevent erosion and provide additional stability.Maintenance of Surrounding Areas

Ensure that the environment surrounding the geotextile bags remains clear of debris that could damage the bags or impede their function. Conduct routine cleanups to remove leaves, rocks, and any foreign materials that may accumulate and threaten the integrity of the bags.Proper Filling Techniques

If your project requires refilling the geo bags, follow proper filling techniques to maintain their structural integrity. Whether using sand, gravel, or another material, ensure the bags are completely filled and sealed to prevent sagging or deformation.Addressing Punctures Immediately

If a puncture is detected, address it without delay. Small punctures can often be repaired with patches made from similar geotextile materials. However, it’s advisable to consult the geo bag manufacturer for specific recommendations on repairs to ensure compatibility.Use Quality Materials

When acquiring Geotextile sand bags, it’s essential to choose products from reputable geo bag manufacturers who provide high-quality materials. Reliable suppliers often offer warranties or guarantees that can provide an added level of assurance regarding the performance and durability of their products.Monitor Performance

Regularly assess how well the geotextile bags are performing their intended function. If the bags become less effective at filtering sediment or controlling erosion, it could indicate that they require maintenance or replacement. Keep an eye on sediment buildup or changes in the landscape around your bags.Documentation

Keep a record of your inspections and maintenance activities for each set of geotextile sand bags deployed. This documentation can provide valuable insights into the performance of the bags over time and inform future maintenance strategies.Educate Yourself and Others

If you are working in a team or community setting, it's crucial to educate everyone involved about the importance of geotextile bag maintenance. Ensure team members understand how to perform regular inspections, report issues, and implement repairs.

Understanding Geo Bag Pricing

When considering maintaining geotextile bags over time, it’s important to factor in Geo bag price. The initial cost of geo bags may vary depending on size, material type, and the manufacturer. Investing in high-quality bags may come with a higher upfront cost but can save money in the long run by minimizing replacement frequency and enhancing performance. Always compare prices from various geo bag manufacturers and consider potential long-term savings that high-quality products may provide.

Conclusion

Efficient maintenance of geotextile bags is integral to their longevity and effectiveness. By keeping these best practices in mind, you can significantly enhance the performance of your geo bags, thereby safeguarding the surrounding environment while achieving your project goals. Regular inspection, proper installation, timely repairs, and use of quality materials are vital steps in ensuring that your geotextile bags serve their intended purpose for years to come.

Frequently Asked Questions (FAQs)

Q1: How long do geotextile bags last?

A: The longevity of geotextile bags can vary based on factors such as the quality of the materials, environmental conditions, and maintenance practices. High-quality bags can last several years if properly maintained.

Q2: Can I reuse geotextile sand bags after a flood?

A: Yes, geotextile sand bags can often be reused after being thoroughly cleaned and inspected for damage. However, if they show signs of excessive wear or contamination, it is advisable to replace them.

Q3: What materials are commonly used to fill geotextile bags?

A: Geotextile bags are commonly filled with sand, soil, or gravel. The choice of filler material depends on the specific application and local availability.