Aquamate 12,000 US Gallon UR3D205 Water Tank Specification

Without a tower, a group would depend on a pump alone, and it must be large sufficient to deal with peak demand quite than average demand. Usage throughout peak hours may be up to five times larger than the every day average, that means the pump would need to be 5 instances bigger, or the city must use 5 times as many pumps. Water towers let cities reduce infrastructure necessities on the pump station and at a number of levels main back to the water therapy facility. Often essentially the most cost-effective answer, a multi-legged tower sometimes has uncovered piping, an exterior ladder, and a catwalk circling the storage tank. In these designs, all the pipes, ladders, and raise methods stay inside an enclosed cylinder supporting the tank.

Texas Metal Tanks

Water towers can vary from a number of thousand dollars to a number of million dollars. In most circumstances, these prices depend on dimension, building, and materials. City or municipality water towers will embrace a multi-factor pumping system. You also can count on to pay around $400 and $1,800 per ton for steel. At about 2.2 pounds of metal per square foot of concrete basis or base, that value adds up rapidly. That piping will include digging over four hundred ft of trench, laying the pipe, after which operating the pipe up the water tower.

The old fashion unlined wood water tanks required clear (no knots) heartwood which is generally unavailable unless somebody is illegally harvesting old development trees. Since the one power concerned in a water tower comes from pressure, it may possibly continue working when there's a failure in the supply system. Service areas can continue receiving water if an influence outage knocks out the pumps or water is low on the therapy facility. Stainless metal is widely thought of superior to other materials in the classes of strength, sturdiness, and hygiene. Manufacturing tanks from stainless-steel maximizes your tank’s expected life expectancy. When hygiene, sturdiness and basic peace of thoughts are paramount, there isn't a different to a Stainless Steel Rainwater Tank. At Phoenix, we imagine high quality, consistency, and a focus to detail guarantee the most effective outcome.

Year "No Service Cost" Warranty

Pedestals stop undesirable trespassers from climbing the construction while providing extra storage and improved aesthetics over multi-legged styles. The difference in water strain between homes in areas with various elevations may be problematic for a single tower. If a home is up to now beneath the tower that the pressure exceeds the standard threshold, it could harm plumbing, home equipment, and water heaters. The galvanized steel tanks are G-90 grade 20 gauge metallic made within the USA. After the tank is constructed, a paint / epoxy lining is utilized to the interior of the tank to supply a protecting barrier between the water and the steel itself. This product is FDA permitted for potable (drinking) water functions and is ANSI / NSF sixty one licensed.

Pioneer water tanks have been trusted for over 27 years as a water tank solution for all sorts of applications. The Pioneer model of water tanks are trusted by clients in over 35 countries as a end result of they’re recognized to be constructed to last. Elevated water tanks and caixa Dagua taçA 10000 litros Preço tanks on towers present for a mixture of pressurized water from gravity feed in addition to a extremely visible statements. Towers could be constructed from both wood or steel in quite lots of types and heights. Many early water towers are actually thought-about historically important and have been included in varied heritage listings around the world.

Pioneer water tanks have been trusted for over 27 years as a water tank solution for all sorts of applications. The Pioneer model of water tanks are trusted by clients in over 35 countries as a end result of they’re recognized to be constructed to last. Elevated water tanks and caixa Dagua taçA 10000 litros Preço tanks on towers present for a mixture of pressurized water from gravity feed in addition to a extremely visible statements. Towers could be constructed from both wood or steel in quite lots of types and heights. Many early water towers are actually thought-about historically important and have been included in varied heritage listings around the world. With a dedication to quality and innovation, Caldwell is dedicated to offering one of the best composite elevated storage tanks in the market. Our pedestal design makes use of the best high quality jump-form concrete pedestal building. Additionally, our pedestal design can embrace a number of storage ranges similar to the designs we routinely offer within the power industry. Tank Connection's RTP (rolled, tapered panel) tank design is available with our prime efficiency coating system for potable water storage, LIQ Fusion 8000 FBE™. The tank cover is out there in the identical development because the tank or with an aluminum geodesic dome.

With a dedication to quality and innovation, Caldwell is dedicated to offering one of the best composite elevated storage tanks in the market. Our pedestal design makes use of the best high quality jump-form concrete pedestal building. Additionally, our pedestal design can embrace a number of storage ranges similar to the designs we routinely offer within the power industry. Tank Connection's RTP (rolled, tapered panel) tank design is available with our prime efficiency coating system for potable water storage, LIQ Fusion 8000 FBE™. The tank cover is out there in the identical development because the tank or with an aluminum geodesic dome.Create your Own Tank Design

Also think about the installation website and how field erected tanks may present challenges. At Phoenix, we imagine high quality, consistency, and attention to element guarantee the most effective outcome. These beliefs are the cornerstone of the providers Phoenix delivers as a total resource for water tower development. From design, engineering, and website preparation—to fabrication, building, and painting—with Phoenix, you get a single supply for excellence. In my experience, the longevity and performance of Tnemec coatings are superior, which is necessary, given the excessive visibility of water tanks. Tank Connection leads the industry in liquid comprise options, with superior coating know-how, versatile design, skilled engineering, and business expertise.

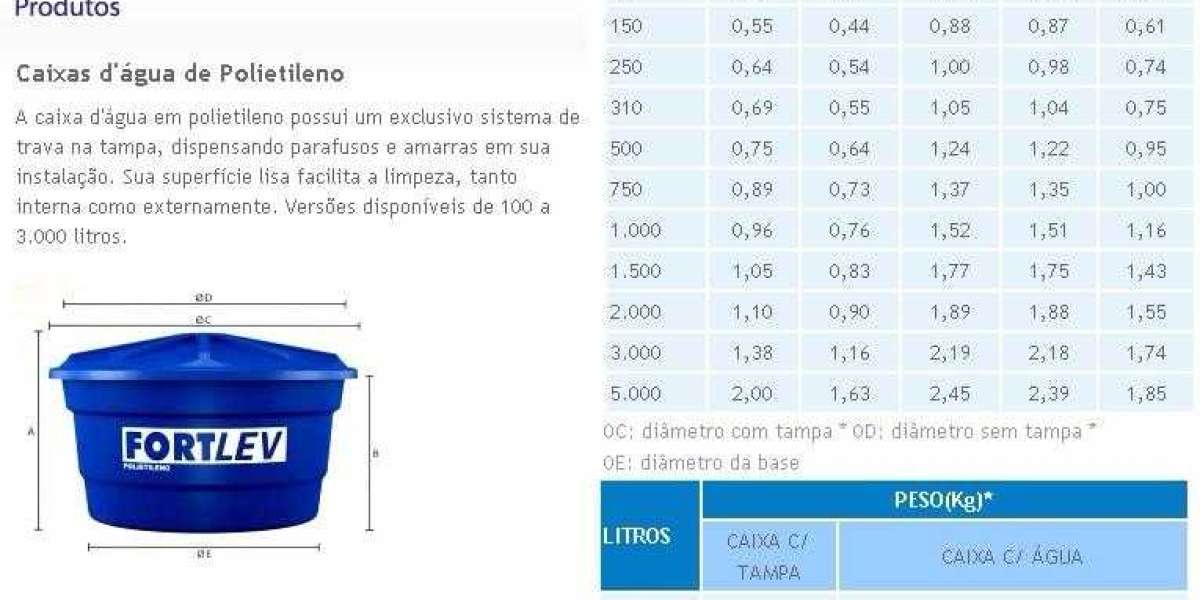

Standard Sizes

The Hydropillar elevated tank is an ideal alternative for patrons who require a large, all-steel construction, robust help pillar, an attractive look and multipurpose interior space. Inspectors look at the tank’s coating, elements, fixtures, surfaces, and basis to make sure that everything is secure and in good working condition. Any imperfections or irregularities noticed during inspection must be repaired in a well timed trend to forestall worsening issues similar to leakage, strain loss, and water quality. Be sure to check your water high quality frequently to avoid sediment buildup and potential contamination from unfastened, leaking, or broken tank elements. Tank Connection development crews installed this Barge-to-Truck transloading terminal with a 127’ tall by 41.5’ diameter RTP bolted Cement Storage Silo to store and transfer cement from ocean barges.